Pigging

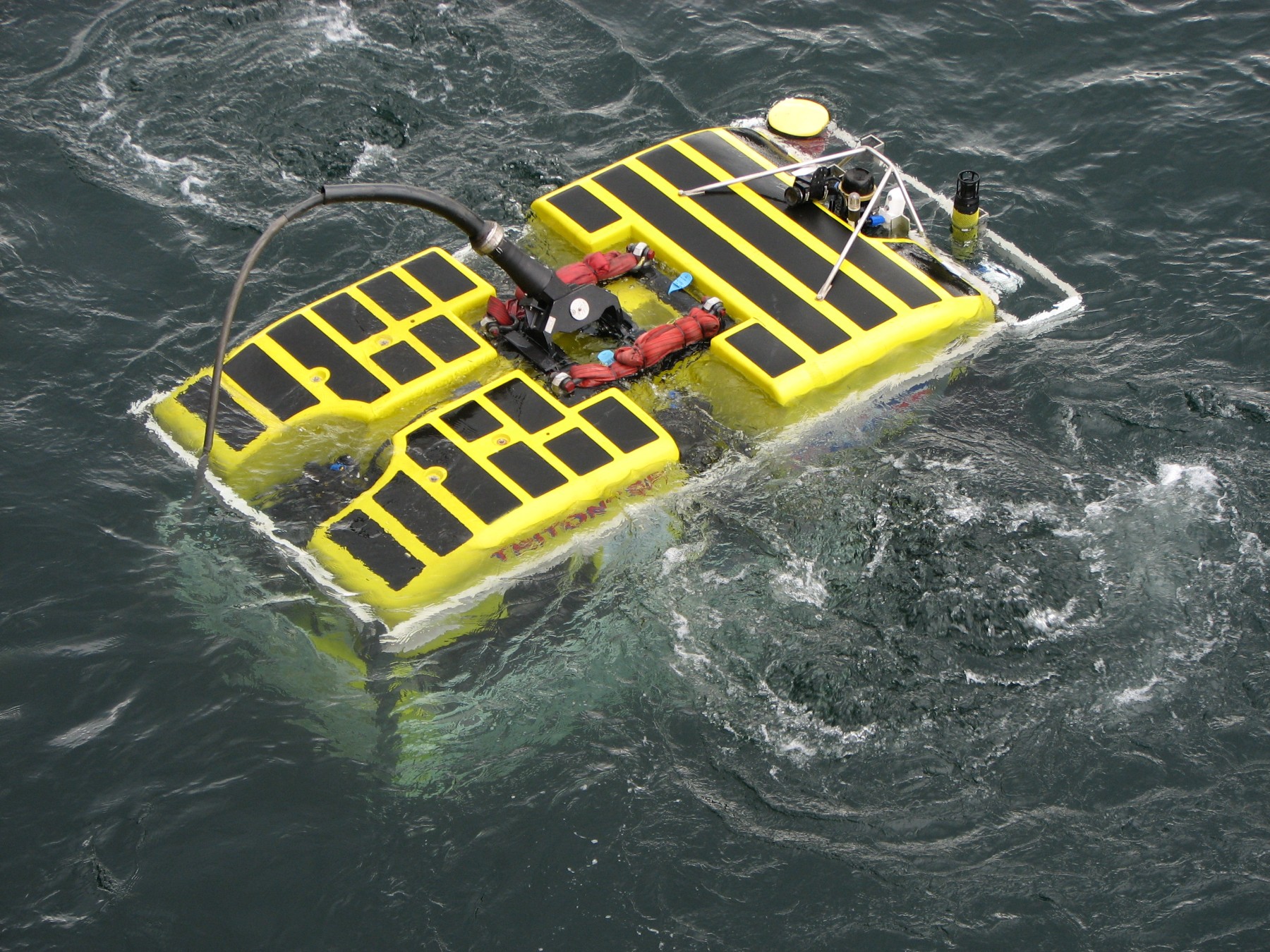

TES provides pigging services to help clients monitor and maintain their subsea pipeline assets. Perhaps you require post-lay construction pigging of a new flowline to check for anomalies. Perhaps you require pigging to clean a pipeline in preparation for final decommissioning. TES will carefully plan these activities and follow through with safe and efficient field execution. Click on the links below to learn how we can help you achieve your goals.

Batch Treatment Pigging

Do you need to batch treat your subsea pipeline or flowline with corrosion inhibitor or biocide for integrity purposes? Do you require batch treatment to remove paraffins and waxes? Technical Energy Solutions (TES) conducts batch injection of speciality chemicals to help you accomplish your maintenance and integrity requirements.

TES will generate a project-specific engineered procedure combined with a risk assessment to enable safe and efficient field execution. By applying this methodical approach, TES helps you to safely treat your subsea pipelines and flowlines. As is customary for TES, parameters are monitored and verified utilizing calibrated instruments to drive safe and efficient operations.

Decommissioning Pigging

Do you need to displace and clean a subsea pipeline or flowline for decommissioning? Do you require long-term lay-up of a subsea pipeline? Technical Energy Solutions (TES) conducts mechanical and chemical cleaning of pipelines and flowlines to meet regulatory requirements. For long-term lay-up, TES can displace operating fluids and preserve the pipeline with nitrogen or preservation chemicals such as corrosion inhibitor, oxygen scavenger, and biocide.

TES will generate a project-specific engineered procedure combined with a risk assessment to enable safe and efficient field execution. By applying this methodical approach, TES helps you decommission or lay-up your pipelines and flowlines. As is customary for TES, parameters are monitored and verified utilizing calibrated instruments to drive safe and efficient operations.

Inspection Pigging

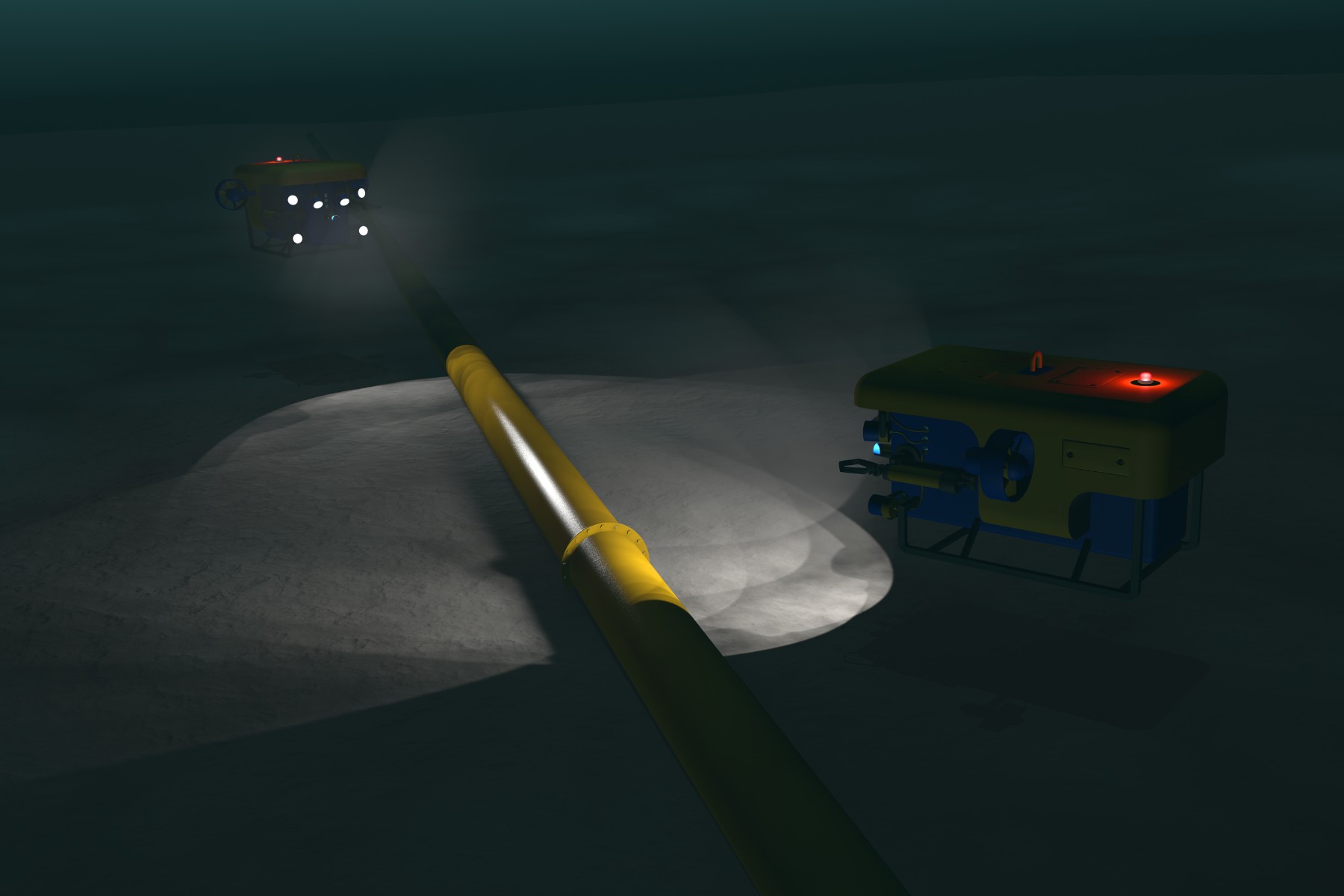

Do you require external support to propel pipeline inspection tools? Do you require subsea pipeline pre-cleaning in advance of pipeline inspection runs? Technical Energy Solutions (TES) conducts controlled pipeline pigging to help you collect a complete set of data on your pipeline inspection run. TES can propel pigs with various fluids including water, nitrogen, or pipeline product. Critically important to successful data collection is enabling sensor contact with the wall of your pipeline. TES also conducts mechanical and chemical cleaning of pipelines to remove debris and prepare them for inspection runs.

TES will generate a project-specific engineered procedure combined with a risk assessment to enable safe and efficient field execution. By applying this methodical approach, TES helps you inspect your pipeline on the first run. As is customary for TES, parameters are monitored and verified utilizing calibrated instruments to drive

safe and efficient operations.

Maintenance Pigging

Do you need to remove debris to increase flowline throughput or reduce pressure loss? Do you require pipeline pre-cleaning in advance of pipeline inspection runs? Technical Energy Solutions (TES) conducts mechanical and chemical cleaning of pipelines to restore operating conditions. TES can propel pigs with various fluids including water, nitrogen, as well as pipeline product.

TES will generate a project-specific engineered procedure combined with a risk assessment to enable safe and efficient field execution. By applying this methodical approach, TES helps you restore your pipeline and flowline operating conditions. As is customary for TES, parameters are monitored and verified utilizing calibrated instruments to drive safe and efficient operations.

Precommisioning Pigging

Do you need to clean, hydrotest, dewater, dry, and inert a new subsea gas pipeline? Technical Energy Solutions (TES) conducts all required pipeline pigging to prepare your new pipeline for start-up. In the case of natural gas pipelines, the following steps are normally required:

· Construction pigging to remove debris and assess for anomalies

· Hydrotesting to relevant code specification

· Dewatering and drying to target dew point

· Inerting to target oxygen content

· Inspection tool baseline assessment

TES will generate a project-specific engineered procedure combined with a risk assessment to enable safe and efficient field execution. By applying this methodical approach, TES helps you meet your pipeline start-up schedule. As is customary for TES, parameters are monitored and verified utilizing calibrated instruments to drive safe and efficient operations.

Stuck Pig Removal

Do you need to remove a stuck pig from your subsea pipeline or flowline? Technical Energy Solutions (TES) conducts stuck pig removal. First, a thorough review of available information is conducted. The knowledge and experience of the TES team is then applied to develop a plan utilizing the various purging, flushing, and pigging tools in the TES toolbox.

TES will generate a project-specific engineered procedure combined with a risk assessment to enable safe and efficient field execution. By applying this methodical approach, TES helps you remove the stuck pigs and restore your pipeline to operating conditions. As is customary for TES, parameters are monitored and verified utilizing calibrated instruments to drive safe and efficient operations.